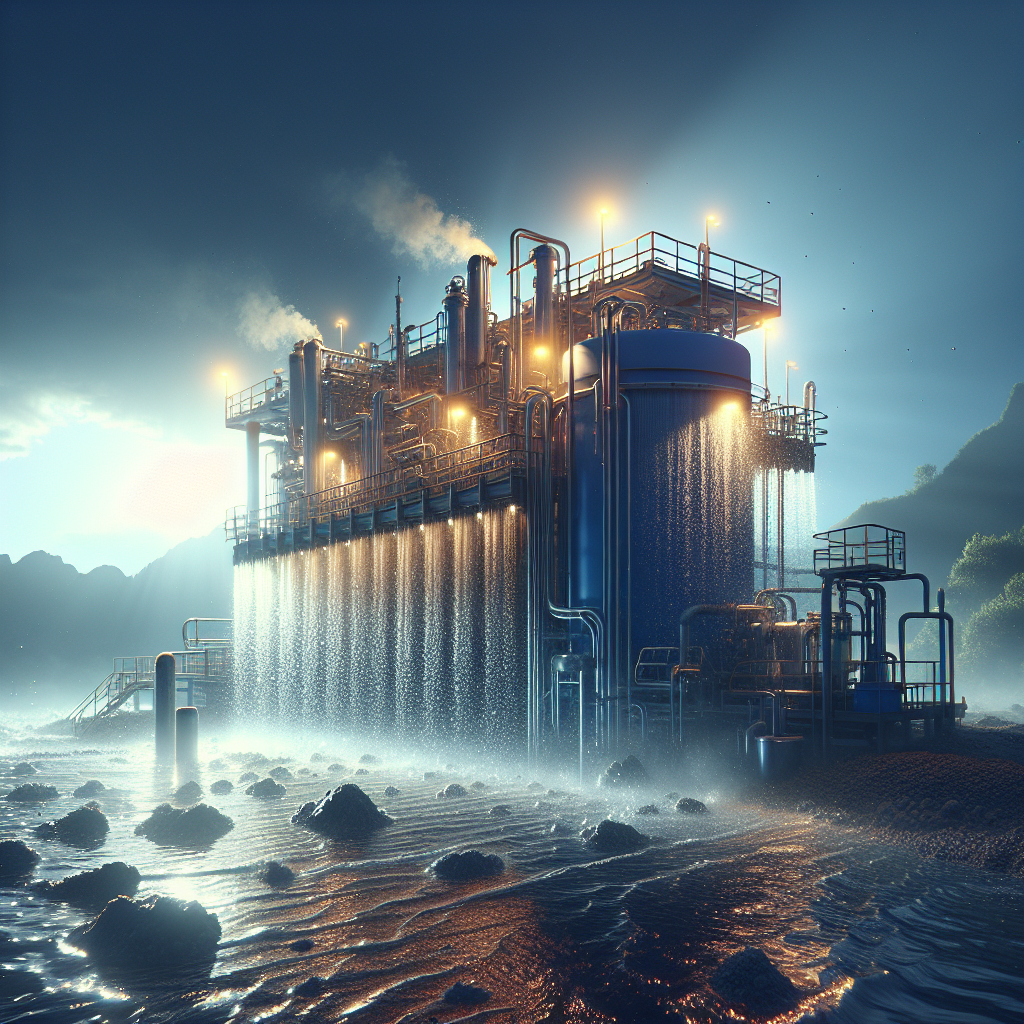

wet chemical scrubber

The Importance of Wet Chemical Scrubbers in Industrial Air Pollution Control

The Importance of Wet Chemical Scrubbers in Industrial Air Pollution Control

Industrial air pollution is a significant concern in today’s world, as it poses a threat to both human health and the environment. To combat this issue, various air pollution control technologies have been developed, one of which is the wet chemical scrubber. Wet chemical scrubbers play a crucial role in reducing harmful emissions from industrial processes, making them an essential component of air pollution control systems.

One of the primary reasons why wet chemical scrubbers are so important is their ability to remove pollutants from exhaust gases. These pollutants can include sulfur dioxide, nitrogen oxides, particulate matter, and volatile organic compounds. By using a combination of water and chemicals, wet chemical scrubbers effectively capture and neutralize these pollutants, preventing them from being released into the atmosphere.

The process of pollutant removal in a wet chemical scrubber involves several steps. First, the exhaust gases are passed through a chamber where they come into contact with a fine mist of water. This water acts as a medium to capture the pollutants, which then dissolve into the liquid. Additionally, chemicals can be added to enhance the scrubbing efficiency and neutralize specific pollutants. The mixture of water, chemicals, and captured pollutants is then collected and treated before being discharged or reused.

Another significant advantage of wet chemical scrubbers is their versatility. These systems can be customized to suit the specific requirements of different industries and processes. For example, in power plants, wet chemical scrubbers are commonly used to remove sulfur dioxide, a major contributor to acid rain. In chemical manufacturing facilities, scrubbers can be designed to target volatile organic compounds, which are harmful to human health and contribute to the formation of ground-level ozone.

Furthermore, wet chemical scrubbers are highly efficient in pollutant removal. The combination of water and chemicals creates a highly reactive environment that facilitates the absorption and neutralization of pollutants. This efficiency is further enhanced by the large surface area provided by the mist of water droplets, ensuring maximum contact between the pollutants and the scrubbing medium. As a result, wet chemical scrubbers can achieve high removal efficiencies, often exceeding 90% for many pollutants.

In addition to their effectiveness, wet chemical scrubbers are also known for their reliability and durability. These systems are designed to withstand harsh operating conditions, such as high temperatures and corrosive gases. They are constructed using materials that are resistant to corrosion, ensuring a long service life with minimal maintenance requirements. This reliability is crucial for industries that operate continuously and cannot afford downtime due to equipment failure.

In conclusion, wet chemical scrubbers play a vital role in industrial air pollution control. Their ability to remove pollutants from exhaust gases, versatility, efficiency, and reliability make them an indispensable component of air pollution control systems. By utilizing wet chemical scrubbers, industries can significantly reduce their emissions and contribute to a cleaner and healthier environment. As the importance of environmental sustainability continues to grow, the use of wet chemical scrubbers will undoubtedly become even more prevalent in the future.